Aloi alwminiwm Cyfres SC actio silindr aer niwmatig safonol gyda phorthladd

Disgrifiad o'r Cynnyrch

Egwyddor weithredol silindrau cyfres SC yw defnyddio grym pwysedd aer i wthio'r piston i symud yn y silindr. Pan ychwanegir pwysedd aer at un porthladd o'r silindr, mae'r piston yn y silindr yn symud o dan bwysau, gan wthio'r ddyfais fecanyddol sy'n gysylltiedig â'r piston. Trwy reoli mewnbwn a gollyngiad pwysedd aer, gellir gwireddu symudiad deugyfeiriadol neu un cyfeiriadol.

Gall y math hwn o silindr ddewis actio dwbl neu ddull actio sengl yn ôl y galw gwirioneddol. Yn y modd actio dwbl, gall y silindr symud ymlaen ac yn ôl o dan bwysau aer; Yn y modd actio sengl, dim ond o dan bwysau un ochr y gall y silindr symud, a gall yr ochr arall ailosod y piston trwy rym dychwelyd y gwanwyn.

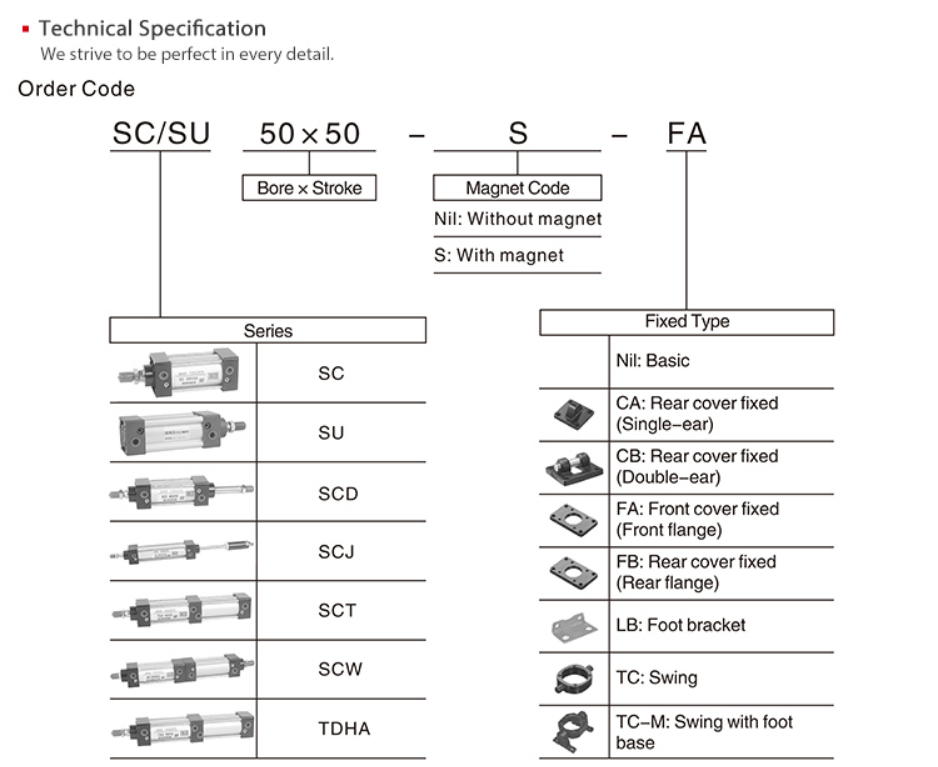

Manyleb Dechnegol

| Maint Bore(mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 |

| Modd Actio | Actio Dwbl | |||||||||

| Cyfryngau Gwaith | Aer Glanhau | |||||||||

| Pwysau Gweithio | 0.1 ~ 0.9Mpa (1 ~ 9kgf / cm2) | |||||||||

| Pwysau Prawf | 1.35MPa (13.5kgf/cm2) | |||||||||

| Ystod Tymheredd Gweithio | -5~70℃ | |||||||||

| Modd Byffro | Addasadwy | |||||||||

| Pellter byffro (mm) | 13-18 | 22 | 25-30 | |||||||

| Maint Porthladd | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | ||||

| Deunydd Corff | Aloi Alwminiwm | |||||||||

| Switsh Synhwyrydd | CS1-F CS1-U SC1-G DMSG | |||||||||

| Sylfaen Sefydlog Switsh Synhwyrydd | F-50 | F-63 | F-100 | F- 125 | F- 160 | F- 250 | ||||

Strôc O Silindr

| Maint Bore(mm) | Strôc Safonol(mm) | Max. Strôc(mm) | Strôc a Ganiateir(mm) | |||||||||

| 32 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1000 | 2000 |

| 40 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 50 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1200 | 2000 |

| 63 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 80 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 100 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 125 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 160 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 200 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

| 250 | 25 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | 1500 | 2000 |

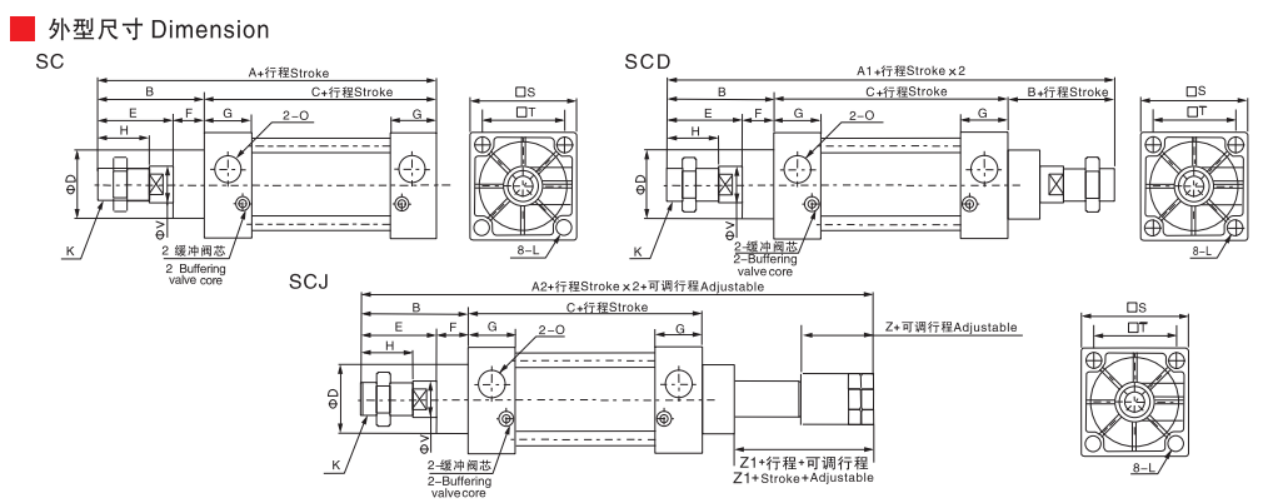

| Maint Bore(mm) | A | A1 | A2 | B | C | D | E | F | G | H | K | L | O | S | T | V |

| 32 | 140 | 187 | 185 | 47 | 93 | 28 | 32 | 15 | 27.5 | 22 | M10x1.25 | M6x1 | G1/8 | 45 | 33 | 12 |

| 40 | 142 | 191 | 187 | 49 | 93 | 32 | 34 | 15 | 27.5 | 24 | M12x1.25 | M6x1 | G1/4 | 50 | 37 | 16 |

| 50 | 150 | 207 | 197 | 57 | 93 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M6x1 | G1/4 | 62 | 47 | 20 |

| 63 | 152 | 209 | 199 | 57 | 95 | 38 | 42 | 15 | 27.5 | 32 | M16x1.5 | M8x1.25 | G3/8 | 75 | 56 | 20 |

| 80 | 183 | 258 | 242 | 75 | 108 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G3/8 | 94 | 70 | 25 |

| 100 | 189 | 264 | 248 | 75 | 114 | 47 | 54 | 21 | 33 | 40 | M20x1.5 | M10x1.5 | G1/2 | 112 | 84 | 25 |

| 125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |

| 160 | 239 | 352 | 332 | 113 | 126 | 62 | 88 | 25 | 38 | 72 | M36x2 | M16x2 | G3/4 | 174 | 134 | 40 |

| 200 | 244 | 362 | 342 | 118 | 126 | 62 | 88 | 30 | 38 | 72 | M36x2 | M16x2 | G3/4 | 214 | 163 | 40 |

| 250 | 294 | 435 | 409 | 141 | 153 | 86 | 106 | 35 | 48 | 84 | M42x2 | M20x2.5 | PT1 | 267 | 202 | 50 |

| SQC125 | 245 | 345 | 312 | 100 | 145 | 60 | 68 | 32 | 40 | 54 | M27x2 | M12x1.75 | G1/2 | 140 | 110 | 32 |